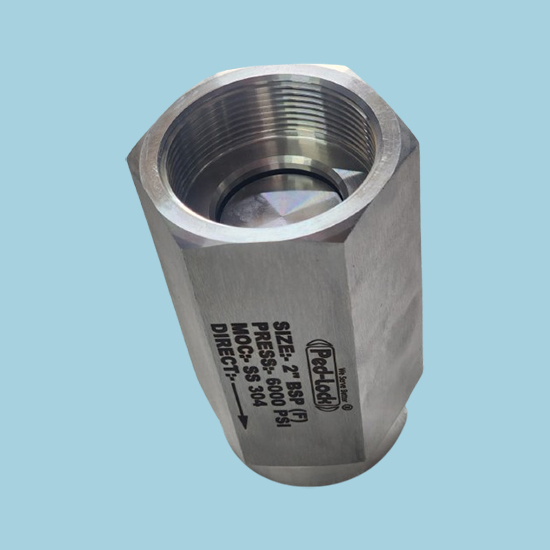

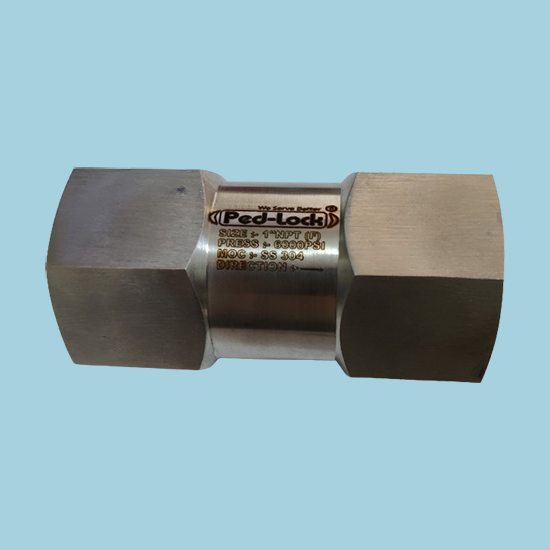

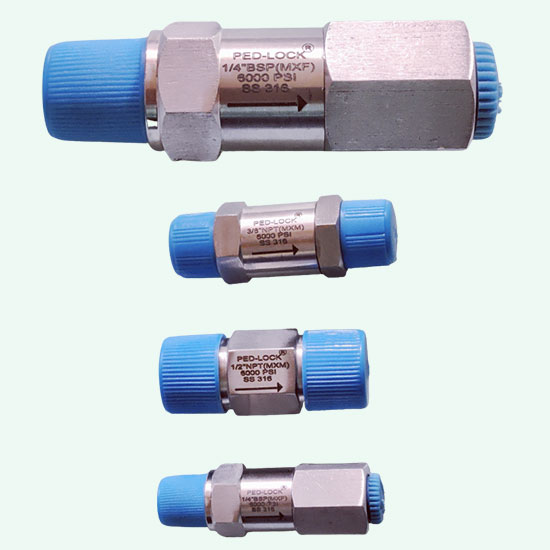

Single PSC Check Valve 3000 PSI

We are one of the reputed names in the industry in offering a quality assured array of Single PSC Check Valve 3000 PSI Manufacturer to our valuable customers. This Single PSC Check Valve is made using optimum quality material and advanced technology. A Check Valve controls the flow direction of fluids and is available in various configurations depending on the application. Single-configuration check valves are designed to prevent backflow in only one direction.

Single-configuration check valves are normally closed – meaning they require positive pressure differential to allow flow – with various termination options including Luers, bond sockets, bond posts, and barbed designs. There are also several opening pressure ratings from precision near-zero opening pressure options to the anti-siphon valves which have higher opening pressures to prevent gravity-induced flow. Medical grade check valves are made with USP Class VI materials deemed safe for use with the human body. Medical grade check valves reduce the risk of contamination, allow seamless priming, and offer higher flow rates. They are ideal for medical device designers focused on infusion, drainage, and irrigation applications.

Technical Specifications

| Rating | Up to 6,000 psi @ up to 250ºF |

|---|---|

| Stem & Body Seal | ‘O-ring (Nitrile & Viton) |

| Tube Size | 1/4” to 3” |

| Connections | Threaded |

| Body | Bar Stock & Forged Steel |

| Pressure rating | 400 kg/cm2 |

| Material | SS, CS and other Material Other as Per Your Requirements |

Key Features

Durable Material

Use durable material that’s corrosion resistance. our in-house design team continuously works to improve strength.

High Strength

The used material is hard & stronger, and the strength of the final product is greater due to the processes performed on it.

Long Service Life

We make this product using the latest technology, and durable material. so this product has a long service life.

Assured Quality

This product is manufactured and controlled to international standards. It undergoes stringent quality tests before dispatch.

Low Maintenance

Due to the design and material, the life of this product is high and it also needs low maintenance.

Manage Pressure

This product is designed to bear maximum applied pressure, that’s why it’s used in critical areas.

Dimensionally Accurate

This product is built under the guidance of a highly qualified expert & needs to pass through several dimensional tests.

Anti Corrosive

The material used to manufacture this product has a characteristic of anti-corrosive.

Applications

Oil & Gas Industry

Chemical Industry

Automobile Industry

Manufacturing Industry

Beverage Industry

Pharmaceutical Industry

Applications

Oil & Gas Industry

Chemical Industry

Automobile Industry

Manufacturing Industry

Beverage Industry

Pharmaceutical Industry

Food Industry

Textile Industry

Testing

Seal Leakage

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Working Pressure

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Performance

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Hydro Test

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Helium Test

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Seismic Test

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Seal Leakage

For seat and seal leakage with a leakage rate of 0.1 std. Cm3.

Working Pressure

Working pressure is a 3000 psi (210 bar)

Performance

The performance of this instrument will be checked with diff. methods.

Hydro Test

Performed with pure water at 1-1/2 times the working pressure.

Helium Test

The helium test is available upon request.

Seismic Test

The seismic test is available upon request.

Seal Leakage

For seat and seal leakage with a leakage rate of 0.1 std. Cm3.

Working Pressure

Working pressure is a 3000 psi (210 bar)

Performance

The performance of this instrument will be checked with diff. methods.

Hydro Test

Performed with pure water at 1-1/2 times the working pressure.

Helium Test

The helium test is available upon request.

Seismic Test

The seismic test is available upon request.

FAQs

Check valves are necessary if there is a risk of condensate backflow. For example, when a trap discharges into a common condensate collection line, there is the potential risk of backflow from condensate discharged from other traps, so as a rule a check valve should be installed.

All our series check valves can be mounted both horizontally or vertically as they are spring activated.

Its purpose is to automatically open while pumps are running, and return to the closed position to prevent reverse flow when the pumps are not in operation. These valves help minimize energy consumption and protect the pumping system from pressure surges and damage from reverse flow.

Check valves also protect the pumps from harm or leakage, so it makes for good practice to install check valves after the pump to prevent any backflow.

If you want to place an order of Single PSC Check Valve 3000 PSI you can contact us on mobile number: +919727192468 or mail us on: info@ped-lock.com or submit a form on “Enquire Now” Button on our website.

Testimonial

- Bleed Valve Traders

- Gauge Glass Cock Manufacturers in Ahmedabad

- Bleed Valve Manufacturers

- Hydraulic Ball Valve Dealer in Gujarat

- Pressure Gauge Accessories

- Safety Valve Manufacturers in Gujarat

- Bleed Valve Manufacturers

- Pressure Gauge Saver Traders in Ahmedabad

- TC End Ball Valve Dealer in Gujarat

- Instrument Valve Traders in Ahmedabad

- Two PSC Check Valve 3000 PSI to 20000 PSI Manufacturers

- Pressure Gauge Saver Manufacturers in Gujarat

- Silicone Hose and Silicone Tubings Dealer in Gujarat

- Hydraulic Valve Dealer in Ahmedabad

- Pressure Gauge Saver Dealer in Gujarat

- 2 Way R-T-H Type Manifold Valves Exporters

- Moisture Separator Manufacturer in Ahmedabad

- PTFE Lined Hose Suppliers in India

- Bleed Valve Suppliers in Gujarat

- Round Body Needle Valve - 300 PSI Exporters in India

- Orifice Plate Flange Manufacturer

- 3 Way R-T-H Type Manifold Valves Suppliers

- Single PSC Check Valve 3000 PSI Suppliers in Gujarat

- Oil and Petrol Hoses Suppliers in Ahmedabad

- Hydraulic Pipe Fittings Manufacturer in Ahmedabad

- SS Corrugated Hose Suppliers in India

- Butterfly Valve Suppliers

- Penal Mounting Female 3 Way / 2 Way Ball Valve

- Square Body Ball Valve 3000 PSI to 10000 PSI Manufacturer

- Round Body Needle Valve - 300 PSI Suppliers

- Hoses Pipe Assemblies Manufacturer

- Precision Pipe Fitting Manufacturer in India

- Hoses Pipe Assemblies Manufacturer in India

- Air Header Manufacturer in India

- Condensate Pot Manufacturer in India

- Check Valve Traders in Ahmedabad

- Compression Tube Fitting Traders in Ahmedabad

- Flow Control Valve Manufacturer in India

- Safety Valve Manufacturer in India

- Pressure Gauge Accessories Exporter

- Gate Valve Exporter

- Pressure Gauge Accessories Manufacturer in India

- Gate Valve Manufacturer in India

- Hydraulic Weld Pipe Fittings Traders in Ahmedabad

- Hydraulic Tube Fittings Traders in Ahmedabad

- Instrument Valve

- Hydraulic Needle Valve

- Panel Mounting OD-Type 3 Way / 2 Way Ball Valve

- Pressure Gauge Snubbers

- Hydraulic Pipe Fittings

- Silicone Hose and Silicone Tubings

- OD Type Needle Valve

- Pressure Gauge Saver

- Bleed Valve

- Industrial Valve

- Penal Mounting Female 3 Way / 2 Way Ball Valve

- Pressure Gauge Cock

- Instrument Accessories

- Needle Valve

- 5 Way R-T-H Type Manifold Valves

Related Products

Two PSC Check Valve 3000 PSI to 20000 PSI

Male To Male Check Valve

OD Type Check Valve