WELCOME TO

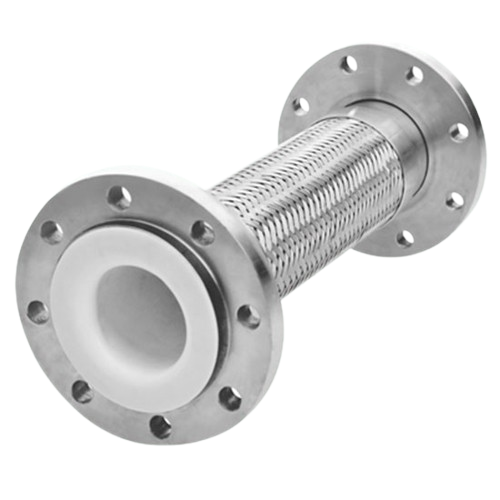

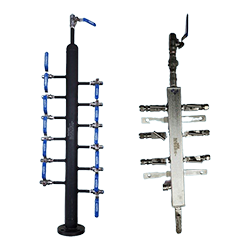

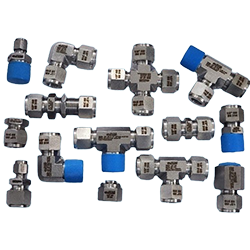

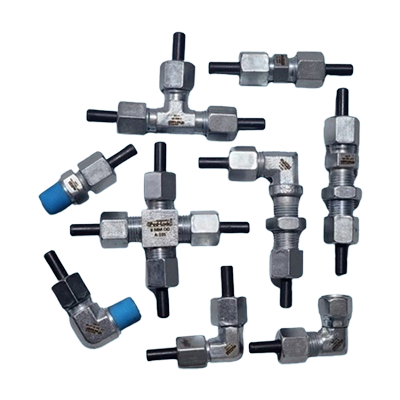

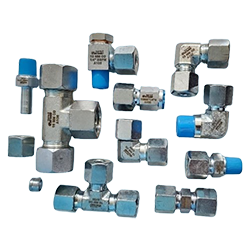

PED-LOCK is the leading Needle Valve Manufacturer, Ball Valve Manufacturer & Exporter and renowned Check Valve Manufacturer in Ahmedabad. We was founded in 1985 since then we have a single purpose of offering great innovative products & services to our customers such as Compression Tube Fittings in Ahmedabad, Precision Pipe Fittings, Air Header.Our aim is to provide the high quality products with a reliable cost. The idea was to capture the white space offered in the Condensate Pot, Gauge Cock, Double Regulating Valve, and Flow Control Valve Product by the fast-growing Companies and Sectors.

OUR

PRODUCTS

Hydraulic Valve Manufacturer

Hydraulic Ball Valve Manufacturer

As a premier hydraulic ball valve manufacturer, both standard and custom hydraulic ball valves are designed for superior performance in high-pressure hydraulic systems. Our ball valves ensure reliable flow control and tight shut-off for a wide array of industrial applications.

Hydraulic Flow Control Valve Manufacturer

We are one of the distinguished hydraulic flow control valve manufacturers, suppliers, producing precise flow control valves engineered for dependable regulation of fluid flow and pressure in process systems.

Whether used in machinery automation, hydraulic circuits, or fluid systems, our flow control valves help optimize system performance with accurate control and robust durability.

Hydraulic Needle Valve Manufacturer

PED-LOCK is a prominent hydraulic needle valve manufacturer and supplier, offering a full range of high-pressure needle valves crafted for precision flow regulation in critical systems.

Manifold Valves Manufacturer

As a reliable manifold valves manufacturer, supplier, we deliver advanced manifold valve solutions suitable for instrumentation and fluid power systems. Our manifold valves are engineered for efficiency, space savings, and rugged performance across varied industries.

Manufacturing

Process

Our

Applications

Automative Industries

Cement Industries

Chemical Industries

Construction Industries

Defence Insdustries

Fertilizer Industires

Food Industries

Furniture Industries

Metal Industries

Metro Industries

Packaging Industries

Paint Industries

Paper Industries

Petrochemicals Industries

Printing Industries

Power Industries

Plastic Industries

Pharma Industries

Solar Industries

Textile Industries

Ped-Lock’s

Culture

Our values and behaviors define the expectations we have for working together and with clients. Although we come from different backgrounds and cultures across the firm, they are what we all have in common. They capture our shared aspirations and expectations, and guide how we make decisions and treat others.

We think about the values as a full set – all are equally critical to our success. We speak up for what’s right, even when that’s the harder option.We stay informed and proactively look for ways to better our world. About each other, about our clients, about empowering everyone to do their best. We know feedback, collaboration and diverse perspectives make our work stronger. At Ped-Lock, we innovate, we test, we iterate and we learn along the way.

Our

Testimonials

Our dealings with the Ped-Lock Valves & Fittings have always been positive experiences, from first enquiry through to order delivery. They provide responsive customer service with accurate and complete documentation, all supplied in a timely… read more

The quality of Ped-Lock Valves & Fittings has always been to the highest standards – added to this a very responsive customer service delivered from quotation stage through to actual delivery of the product. This… read more

we are using them in our lines and find that they are long lasting and easy to operate and hadle. We feel proud to be associated with your esteemed organisation. The Quality of every product… read more

We have been using Ped-Lock Valves & Fittings in our facility for the past 30 years and are extremely satisfied with the quality and services. They are the best Needle Valve Manufacturer & Exporters, Ball… read more

Our relationship with Propel Valves goes more than 20 years. They are not only our Needle Valve suppliers, but also been our dependable partners for new requirements and developments. They are the precision Ball Valve… read more

We have been using Ped-Lock Valves & Fittings in our facility for the past 30 years and are extremely satisfied with the quality and services. They are the best Needle Valve Manufacturer & Exporters, Ball… read more