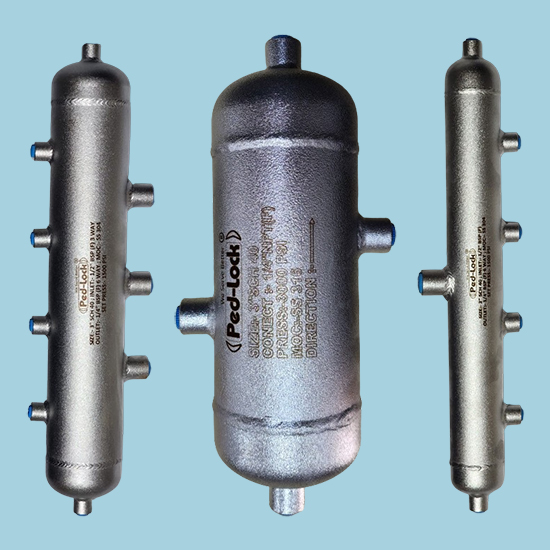

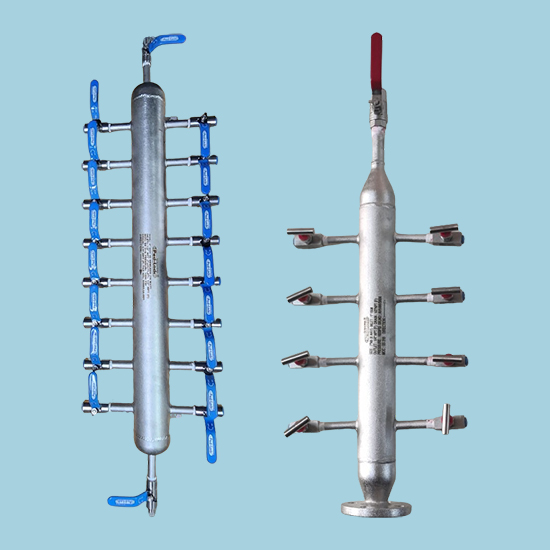

Condensate Pot

Ped Lock is known as one of the biggest Condensate Pot manufacturers in India. Condensate Pot are one of our most popular Metal Market goods. Condensate Pot come in a range of sizes, shapes, and dimensions, and they can also be modified to match our customer’s specific requirements. We deliver Condensate Pot in the proper number and with the suitable quality to meet the needs of various industrial sectors.

The prime purpose of a condensate or Seal Pot is to hold foreign material and any liquid resulting from vapor (condensate). This avoids the metering system from being damaged. The condensate pot has a pipe with a 4-inch diameter which is fixed horizontally between the flow meter and gauge. It is employed as a blockade between the chief line and the secondary mechanism to measure steam or any other vapors which may turn into a liquid state in order to ensure compatibility with the secondary apparatus. Being one of the leading Seal Pot Manufacturers, we produce condensate pots in numerous materials like stainless steel, alloy steel, Monel, Hastelloy, and carbon steel. Seal pots are widely employed in processing industries in addition to power plants, steel, refineries, and petrochemical business. We are a renowned Condensate Exporter/Seal Pot Exporter.

Technical Specifications

| Rating | Up to 6,000 psi @ up to 250ºF |

|---|---|

| Tube Size | 3” 4” 6” |

| Outlet Connections | ½” |

| Inlet Connections | ½” |

| Drain connections | ½” |

| Pot connection | ½” |

| Material | SS, CS, and other Material Other as Per Your Requirements |

Key Features

Durable Material

Use durable material that’s corrosion resistance. our in-house design team continuously works to improve strength.

High Strength

The used material is hard & stronger, and the strength of the final product is greater due to the processes performed on it.

Long Service Life

We make this product using the latest technology, and durable material. so this product has a long service life.

Assured Quality

This product is manufactured and controlled to international standards. It undergoes stringent quality tests before dispatch.

Low Maintenance

Due to the design and material, the life of this product is high and it also needs low maintenance.

Manage Pressure

This product is designed to bear maximum applied pressure, that’s why it’s used in critical areas.

Dimensionally Accurate

This product is built under the guidance of a highly qualified expert & needs to pass through several dimensional tests.

Anti Corrosive

The material used to manufacture this product has a characteristic of anti-corrosive.

Applications

Oil & Gas Industry

Chemical Industry

Automobile Industry

Manufacturing Industry

Beverage Industry

Pharmaceutical Industry

Applications

Oil & Gas Industry

Chemical Industry

Automobile Industry

Manufacturing Industry

Beverage Industry

Pharmaceutical Industry

Food Industry

Textile Industry

Testing

Seal Leakage

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Working Pressure

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Performance

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Hydro Test

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Helium Test

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Seismic Test

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Seal Leakage

For seat and seal leakage with a leakage rate of 0.1 std. Cm3.

Working Pressure

Working pressure is a 3000 psi (210 bar)

Performance

The performance of this instrument will be checked with diff. methods.

Hydro Test

Performed with pure water at 1-1/2 times the working pressure.

Helium Test

The helium test is available upon request.

Seismic Test

The seismic test is available upon request.

Seal Leakage

For seat and seal leakage with a leakage rate of 0.1 std. Cm3.

Working Pressure

Working pressure is a 3000 psi (210 bar)

Performance

The performance of this instrument will be checked with diff. methods.

Hydro Test

Performed with pure water at 1-1/2 times the working pressure.

Helium Test

The helium test is available upon request.

Seismic Test

The seismic test is available upon request.

FAQs

They are used to condense the fluid upstream of the differential pressure transmitter. Installed at the same height, they allow accurate measurement by maintaining a constant condensate height in the impulse lines above the differential pressure transmitter.

The 4 inch diameter pipe for the condensate pot is positioned horizontally between the flow meter and gauge. In order to ensure compatibility with the secondary apparatus, it serves as a blocker between the primary line and the secondary mechanism to measure steam or any other vapors

Definitely Yes. We have a special team for the checking of quality. All Condensate Pot are 100% factory tested prior shipment.

Yes. You can get Condensate Pot according to your location. We are supplying Seal Pot entire in India without any physical boundaries.

After placing the order you can contact the Condensate Pot Manufacturer through mobile No. +919727192468 and can gate information about your order.

Testimonial

- Ped-Lock Condensate Pot

- Condensate Pot

- Condensate Seal Pot

- Seal Pot

- Industrial Condensate pot

- Industrial Seal Pot

- Condensate Pot Parts

- Condensate Pot Types

- Condensate Pot Size

- Condensate Pot Prices in India

- Condensate Pot Uses

- Online Condensate Pot

- Industrial Condensate Pot Manufacturers

- Top 10 Condensate Pot Manufacturers in India

- Condensate Pot Manufacturers

- Condensate Pot Manufacturers near me

- Condensate Pot Manufacturers in Ahmedabad

- Condensate Pot Manufacturers in Gujarat

- Condensate Pot Manufacturers in India

- Condensate Pot Suppliers in Ahmedabad

- Condensate Pot Suppliers in Gujarat

- Condensate Pot Suppliers in India

- Condensate Pot Exporters in Ahmedabad

- Condensate Pot Exporters in Gujarat

- Condensate Pot Exporters in India

- Condensate Pot at Best price In India

- Pressure Gauge Cock Manufacturer in Ahmedabad

- Hydraulic Needle Valve Suppliers in Gujarat

- Condensate Pot Suppliers in India

- Thermowell Manufacturer in Ahmedabad

- Pressure Gauge Cock Suppliers

- Flow Control Valve Manufacturer

- Safety Valve Manufacturer

- Precision Pipe Fitting Manufacturer in India

- Hoses Pipe Assemblies Manufacturer in India

- Air Header Manufacturer in Ahmedabad

- Condensate Pot Manufacturer in Ahmedabad

- Air Header Manufacturer in India

- Condensate Pot Manufacturer in India

- Gauge Cock Suppliers

- Double Regulating Valves Suppliers

- Needle Valve Manufacturer

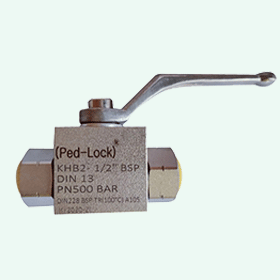

- Ball Valve Manufacturer

- Check Valve Manufacturer in Ahmedabad

- Compression Tube Fitting Manufacturer in Ahmedabad

- Precision Pipe Fitting Manufacturer in Ahmedabad

- Auto Drain Valve

- Hydraulic Check Valve

- Flange End Ball Valve

- Thermowell

- CO2 Hose

- Precision Pipe Fittings

- Male to Male Check Valve

- Hydraulic Hose Assembly

- Pressure Gauge Saver

- Pressure Relief Valve

- Safety Valve

- Globe Valve

- Pressure Gauge Cock

- Direction Valve

- Oil and Petrol Hoses

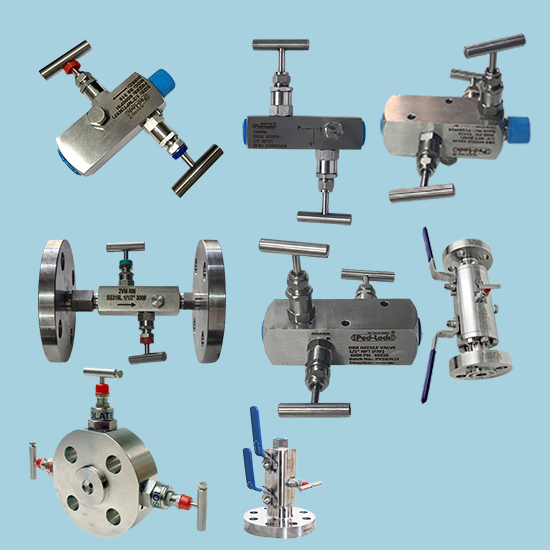

Related Products

Air Header

Vent Valve

Pressure Relief Valve

Roto Seal Coupling

Bleed Valve

Quick-Release Valve

Moisture Separator

Auto Drain Valve

Instrument Hookups

Sampling Bottle / Sampling Cylinder

Orifice Valve