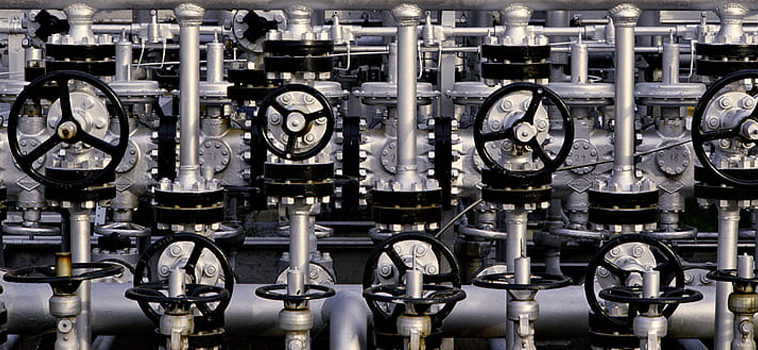

Hydraulic Valves – Types and Components

A mechanical device that controls the flow of the liquid, usually by opening and closing is referred to as a valve. The primary purpose of a hydraulic valve is to direct the flow of a liquid medium that will move actuators and loads through the hydraulic system. There are various types of hydraulic valves and it is important to choose the right one to get the best results.

What are the different types of hydraulic valves?

Directional Control Valves

There are five types of directional control valves:

- Check valves

- Shuttle valves

- Two-way valves

- Threeway valves

- Fourway valves

Pressure Control Valves

A pressure control valve helps in maintaining a set pressure in the hydraulic system. Pressure control valves are used mainly in industries where keeping system pressure below a desired upper limit is crucial such as oil and gas industries.

There are types of pressure control valves:

- Relief valves

- Constant pressure reducing valves

- Sequence valves

- Counterbalance valves

- Over center valves

- Unloading valves

Flow Control Valves

Flow control valves regulate the flow rate at the throttling point by increasing or decreasing the opening of a hydraulic circuit. The flow rate helps in determining the rate of energy transfer at any given pressure.

There are five most common types of flow control valves:

- Gate valves

- Globe valves

- Pinch valves

- Diaphragm valves

- Needle valves

Reliable Partner for all types of Industrial Products

Ped-Lock Valves & Fittings has been supplying a wide range of industrial products including all types of industrial valves. With the aim of providing the best products to our customers, we test all our products for reliability and durability even in the harshest conditions before delivering it.