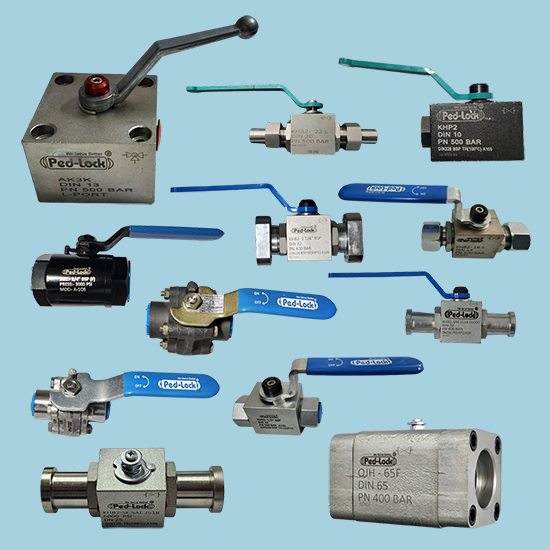

hydraulic Check Valve

We are one of the pioneered Hydraulic Check Valve Manufacturer and Hydraulic Check Valve Supplier. We have a world-class manufacturing facility and expert technicians to produce a complete range of Hydraulic Check Valves. Designed in line with quality-centric parameters defined by international bodies, these Hydraulic Check Valves are broadly used in various applications suitable for steam, hydraulics, oil and gas media, and all high-pressure fluid in various industries. These Flow Control & Check Valves are catered to the clients in different customized options like size and pressure handling power as per their need.

These Hydraulic Check Valves are utilized in water-driven frameworks as it permits the free progression of liquid the other way by halting the stream one way efficiently without a leak. We are Hydraulic Check Valve Exporter provides these valves to all abroad clients at a minimum cost price.

Technical Specifications

| Rating | Up to 7,000 psi @ up to 250ºF |

|---|---|

| Stem & Body Seal | ‘O-ring (Nitrile & Viton) |

| Tube Size | 1/4” to 3” |

| Connections | Threaded |

| Body | Bar Stock & Forged Steel |

| Pressure rating | 500 kg/cm2 |

| Material | SS, CS, and other Material Other as Per Your Requirements |

Key Features

Durable Material

Use durable material that’s corrosion resistance. our in-house design team continuously works to improve strength.

High Strength

The used material is hard & stronger, and the strength of the final product is greater due to the processes performed on it.

Long Service Life

We make this product using the latest technology, and durable material. so this product has a long service life.

Assured Quality

This product is manufactured and controlled to international standards. It undergoes stringent quality tests before dispatch.

Low Maintenance

Due to the design and material, the life of this product is high and it also needs low maintenance.

Manage Pressure

This product is designed to bear maximum applied pressure, that’s why it’s used in critical areas.

Dimensionally Accurate

This product is built under the guidance of a highly qualified expert & needs to pass through several dimensional tests.

Anti Corrosive

The material used to manufacture this product has a characteristic of anti-corrosive.

Applications

Oil & Gas Industry

Chemical Industry

Automobile Industry

Manufacturing Industry

Beverage Industry

Pharmaceutical Industry

Applications

Oil & Gas Industry

Chemical Industry

Automobile Industry

Manufacturing Industry

Beverage Industry

Pharmaceutical Industry

Food Industry

Textile Industry

Testing

Seal Leakage

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Working Pressure

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Performance

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Hydro Test

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Helium Test

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Seismic Test

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit.

Seal Leakage

For seat and seal leakage with a leakage rate of 0.1 std. Cm3.

Working Pressure

Working pressure is a 3000 psi (210 bar)

Performance

The performance of this instrument will be checked with diff. methods.

Hydro Test

Performed with pure water at 1-1/2 times the working pressure.

Helium Test

The helium test is available upon request.

Seismic Test

The seismic test is available upon request.

Seal Leakage

For seat and seal leakage with a leakage rate of 0.1 std. Cm3.

Working Pressure

Working pressure is a 3000 psi (210 bar)

Performance

The performance of this instrument will be checked with diff. methods.

Hydro Test

Performed with pure water at 1-1/2 times the working pressure.

Helium Test

The helium test is available upon request.

Seismic Test

The seismic test is available upon request.

FAQs

Check valves are the simplest form of hydraulic devices in that they permit free oil or water flow in one direction and block oil or water flow in the opposite direction. Oil or water is flowing in from the left side port, through the check valve and out the right side port. If the pressure equalizes or is higher in the right side port, the check valve will close and block flow in the opposite direction.

- Material Selection

- Performance Requirements

- Type and Size

- Maintenance

- Special Requirements

Yes, Hydraulic Check valve are fluid control devices that restrict the flow of media in a piping system to one direction.

Check valves have more material options because they do not rest in water. Foot valves are used for suction lift applications, like a well pump. Check valves are applicable for pump systems and any system that requires backflow prevention. Foot valves only go at the end of a pump’s suction line.

Yes, this consists of two valves in one block. When operating a double acting ram the extend and retract speeds will differ, due to the different fluid volumes. From our control valve full flow is permitted through in one direction whereas the other side is flow controlled and/or vice versa, in this way the different valve settings will optimize the actuator speeds.

Testimonial

- CO2 Hose Traders in Gujarat

- Pressure Relief Valve Dealer in Gujarat

- Mini Ball Valve Dealer

- Globe Valve Dealer in Ahmedabad

- Gauge Glass Cock Manufacturers in India

- Two PSC Check Valve 3000 PSI to 20000 PSI Manufacturers in India

- Auto Drain Valve Traders in Gujarat

- Quick-Release Valve Manufacturers in Gujarat

- Pressure Gauge Syphon Manufacturers

- PTFE Lined Hose Traders

- Hydraulic Ball Valve Traders in Gujarat

- Pressure Gauge Cock Traders in Gujarat

- Gauge Glass Cock Dealer in Ahmedabad

- Thermowell Traders

- Instrument Accessories Dealer

- Pharma & Dairy Hose

- Multiport Gauge Valve Suppliers

- Square Body Ball Valve 3000 PSI to 10000 PSI Suppliers in Gujarat

- TC End Ball Valve Exporters

- Instrument Hookups Suppliers

- Butterfly Valve Manufacturer in Gujarat

- Sampling Bottle / Sampling Cylinder

- Hydraulic Weld Pipe Fittings Manufacturer

- Male to Male Needle Valve Manufacturer in Gujarat

- TC End Ball Valve Suppliers in Gujarat

- 3 Way Needle Valve Manufacturer

- Mini Ball Valve

- Needle Valve

- PTFE Lined Hose Suppliers in Ahmedabad

- Direction Valve Manufacturer

- Hydraulic Tube Fittings Suppliers

- Precision Pipe Fitting Manufacturer in Gujarat

- Hoses Pipe Assemblies Manufacturer in Gujarat

- Gauge Glass Cock Exporter

- Manifold Valve Exporter

- Hydraulic Weld Pipe Fittings Traders in Ahmedabad

- Hydraulic Tube Fittings Traders in Ahmedabad

- Globe Valve Manufacturer in Gujarat

- Butterfly Valve Manufacturer in Gujarat

- Precision Pipe Fitting Suppliers

- Hoses Pipe Assemblies Suppliers

- Globe Valve Traders in Gujarat

- Butterfly Valve Traders in Gujarat

- Hydraulic Weld Pipe Fittings Traders in India

- Hydraulic Tube Fittings Traders in India

- Hydraulic Ball Valve

- Single PSC Check Valve 3000 PSI

- Flange End Ball Valve

- Compression Tube Fittings

- Hydraulic Weld Pipe Fittings

- SS Corrugated Hose

- Globe Valve

- Air Header

- Square Body Needle Valve - 300 PSI

- Safety Valve

- Sampling Bottle / Sampling Cylinder

- Ball Valve

- TC End Needle Valve

- 3 Way R-T-H Type Manifold Valves

- 3 Way Needle Valve

Related Products

Hydraulic Ball Valve

Hydraulic Ball Valve Manufacturer in India makes ball valves of different types and material makes.

Flow Control Valve

Ped Lock is one of the major Flow Control Valve Manufacturers, Suppliers & Exporters from India. Flow Control..

Direction Valve

We are among the reputed organizations and highly engaged in Direction Valve Manufacturer in India and provide a premium...

Minimize Coupling / Test Coupling

Ped Lock is one of the leading Manufacturer and Supplier of Minimize Test couplings. We provide superior quality Minimize...